More than an aluminium foundry, we accompany your project of raw casting part or finite mounted subunit, from its elaboration to series production and also prototypes.

Manufacturing capabilities

Dejoie provides several technologies regarding forming process.

- Gravity die casting method, sand gravity die-prototyping.

- Use of sheet-metal or machined parts.

- Weight of the part : from 50g to 20 kg.

- Medium and large production batches, from 100 to 50 000 parts per year.

- Supply of raw, semi-finished and finished products.

Main equipments

We acquired special know-how and complete as well as modern manufacturing equipments, to answer your needs.

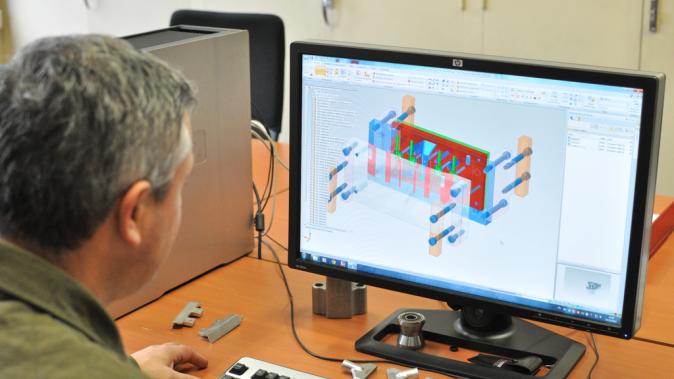

- Engineering office (CAD, CAM, digital simulation).

- ROHS compliant chromium-free surface treatment processing chain.

- Booth for liquid paint application.

- Numerical control machine for milling, turning, electro-erosion jobs.

- Assembly and packaging workstations.

Dejoie is your partner all through the process, from the study of your project to the mass production.

Assisted design

We assist you in the value analysis, the definition of specifications, the study of parts and tools

Design proposal

In partnership with practice and graduate schools of design we can submit design proposals for your aluminium casting part or subunit.

Model making / Prototype

The manufacturing of a prototype, model representative of the production version enables you to validate the conception of your casting part or subunit.

Digital simulation

To ensure tools costs efficiency and reduce preprocessing time, we use digital fillig level simulation. This enables us to work on the defects that may arise during casting, before machining the mould blocks. The aim is :

- Reducing costs of obtaining tools

- Reducing time of implementation

Subunits manufacturing

We ensure the project management on various processes and materials (casting, sheet metal, plastics processing) necessary for the manufacturing of your subunits.

Finishing process

The painting in liquid application, anti-graffiti or anti-poster coating for your aluminium casting parts or subunits is made in our own workshops (except for powder paint by subcontracters).

We also ensure the project management on requests for surface treatments (anodization, heat treatment...) in compliance with the ROHS Directive.

Assembly

From the manufactured components we can ensure the creation of pre-assembled or finished subunits.

We shall remain at your disposal to manage integration of other parts or accessories (electrical, display, electronic) supplied by yourselves or ourselves.

Logistics

We ensure all logistics concerning the delivery of your aluminium raw part or subunit.

- Product management customer's ownership (tools, accessories)

- Specific packaging (number of parts per cardboard, dimensions of the pallet) with indication of your referencing.

- Delivery on logistics platform

- Delivery on site